Die Lubrication System (Auto srayer)

In order to produce products in fully automatic Die-casting production facilities, the lubrication process must be done automatically. In addition, regular and equal lubrication is extremely important in terms of product quality. In other words, it is inevitable to use such mould spraying systems both in terms of production, mould life and product quality. HTE controls have developed mould lubrication systems, and mould spraying machines. It increases the efficiency of your production line and adds value to you by ensuring that the products are produced at the same quality.

Benefits & features of Die lubrication systems (Auto Sprayer)

- Increases the efficiency of the production process

- Increases product quality

- significant increase in mould life

- Shortens production time

- Precise position control thanks to high torque servo motor and drivers.

- User-friendly Interface.

- Teach mode to easily program spraying, and easily add/remove steps on any steps of the program.

- Ejector, plunger and 2 sets of Core pull forward-backwards control during lubrication and air blast.

- Programmed steps control. ( Some steps of the lubrication program can be applied at regular intervals as per die requirement)

- Capability to start the horizontal movement with die opening.

- Capability to send spray finish signal after vertical up end position.

- Automatic lubrication system for linear guides.

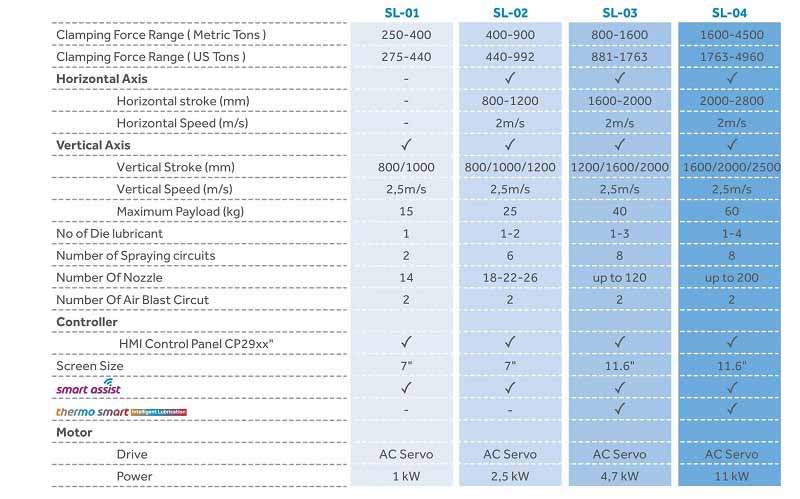

Specifications